Categories

New products

-

Lens Ring Joint Gasket

China Lens Ring Joint Gasket manufacturer,supply Lens Ring Joint Gasket to your requirements. More quality Lens Ring Joint Gasket product info of Kaxite click here.

-

Double Jacket Gasket

China Double Jacket Gasket manufacturer,supply Double Jacket Gasket to your requirements. More quality Double Jacket Gasket product info of Kaxite click here.

-

Corrugated Gaskets

China Corrugated Gaskets manufacturer,supply Corrugated Gaskets to your requirements. More quality Corrugated Gaskets product info of Kaxite click here.

-

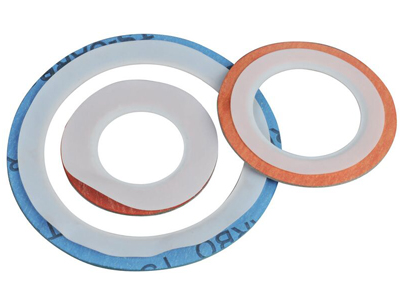

PTFE Envelope Gasket

China PTFE Envelope Gasket manufacturer,supply PTFE Envelope Gasket to your requirements. More quality PTFE Envelope Gasket product info of Kaxite click here.

-

CGFO Packing

China CGFO Packing manufacturer,supply CGFO Packing to your requirements. More quality CGFO Packing product info of Kaxite click here.

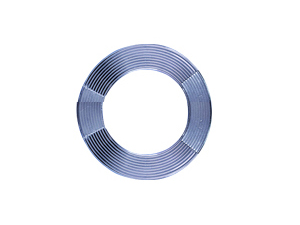

Super Graphite Valve Packing

Super Graphite Packing specially for high pressure valves, braided from expanded graphite yarns with corrosion inhibitor, reinforced with inconel wire. Each yarn is round braided with inconel mesh outside again. The mesh is jacketed.

Description

Flexible graphite packing braided from expanded graphite yarns, reinforced of cotton fiber, glass Super Graphite Packing specially for high pressure valves, braided from expanded graphite yarns with corrosion inhibitor, reinforced with inconel wire. Each yarn is round braided with inconel mesh outside again. The mesh is jacketed.The jacketed materials: stainless steel, inconel, copper, etc.

Kaxite P404AM -- Graphite packing wrapped with Aramid Mesh

Each yarn is wrapped with aramid filament. The high strength aramid mesh make the packing three times more resistant to extrusion and increase the pressure handing capabilities.

Typical Application

> It can handle most chemical, acids and alkalis

> Excellent for use in steam turbines, high temperature motor-actuated valves and for high temperature and high pressure valve applications in general.

Prime Features

> The exclusive packing is formable, yet tough.

> Cost-effective as well as a confident

Technical Data

| Material | 100% Expanded Graphite Yarn and Metal Mesh (Aramid Mesh) | |

| Temperature Range |

-200 up to +555 -200 up to +850 |

|

| Process | Reciprocating | 30 Mpa |

| Valves | 48 Mpa | |

| PH | 0~14 | |

| Density | 1.5~1.75 g/cm3 | |